Rapid Chloride Permeability Test (RCPT) is a measure of concrete permeability against chloride penetration using accelerated method. The purpose is to get the total charge passed (coulomb) in the specimen which can be further evaluated to examine the chloride penetration initiation time from the concrete surface until it touches the steel rebar in the reinforced concrete structures. The term “Virtual” has a meaning that the RCPT is numerically computed (Virtual RCPT), see Bentz [1]. In this research, the VRCPT formulation is coupled with the mix design formulated in ACI 211.1 and the Genetic algorithm to get the optimal solution of the mix design composition. The objective function inside the GA is the minimum material cost required which satisfy the desired initiation time based on one dimensional 2nd Fick’s law.

Introduction. The chloride penetration initiation time is affected by several factors such as the concrete cover, the environmental condition, and the concrete mixture composition. A thicker concrete cover will provide longer initiation time due to the travel distance of the chloride penetration from the concrete surface to the reinforcing bar is longer. However, using a thick concrete cover is not without problems. If the structural elements are bending dominated such as beams and slabs, the concrete cover is more vulnerable against cracks, and the actual thickness of the concrete cover may be less than specified. For concrete slabs, additional check should be carried out to estimate the cracks in slabs due to service load should be within the code limits.

The environmental condition affects the chloride content in the concrete surface and is depends on the climate, the location of the structural elements (e.g. splash zone) and the distance to the chloride sources. Concrete mixture composition also plays an important role, concrete with low water/cement (w/c) ratio is less permeable in comparison to that of concrete with high w/c ratio. Filler materials such as fly-ash which is finer than cement and it has silica content (SiO2) can improve the concrete permeability. A pure silica fume is more effective than fly-ash as it contains almost 99% SiO2. However, it is more expensive than fly-ash.

In the above, the boundary conditions (BC) are the concrete cover thickness, the environmental condition, and the materials cost. Ideally, a trial and error using RCPT should be carried out to determined the optimum concrete mixture composition by setting the required concrete permeability which usually measured by using the total charge passed in Coulombs. Alternatively, the engineer can estimate the total charge passed numerically by using VRCPT method developed by Bentz [1].

VRCPT works by analyzing the concrete mixture composition, the concrete condition (saturated or sealed) and the temperature during the test. For detail on the basic formulation, see [1]. However, a more detailed formula is described in Piscesa et. al. (2010) [2]. Finding the optimum concrete mixture composition by considering the BC (concrete cover thickness, the environmental condition, and the material cost) is one of the problems. One of the most convenient ways is to use a trial and error method, however, in this article, rather than using a trial and error, an optimization method using the genetic algorithm coupled with the ACI 211.1 Mix Design and VRCPT is developed as a stand-alone computer program.

Program Installation and Tutorial. The developed program is called Mix Design with VRCPT V1.3.8. The program can be used either with or without optimization. If there is no optimization, the user needs to input the data manually, and the user can get the amount of the total charge passed, as well as the chloride penetration initiation time with fixed data on the concrete cover and the chlorides content at the concrete surface.

The programs is free to be distributed and can be downloaded from this >>>link<<<. In order to run properly, the minimum computer system requirements is:

- Processor Pentium III 450 Mhz or eqivalent (XP), Processor Pentium III 600 Mhz or eqivalent (Vista), Processor Pentium III 1 GHz on Windows 7 (32 Bit/64Bit).

- 128 MB Ram (XP), 512 MB Ram (Vista). 1 GB Ram (Windows 7).

- 10 MB Harddisk Space.

- Microsoft .Net Framework 3.5 SP1, can be downloaded from this >>>link<<<. Please scroll down to the end of the page and download the Full Package or directly from this >>>link<<<.

In this article’s the basic tutorial of how to use the program is presented. Figure 1a shows the main form of the VRCPT program. The tutorial will be divided into three major steps:

- Mix Design with ACI 211.1

- Virtual Rapid Chloride Penetration Test, and

- Genetic Algorithm

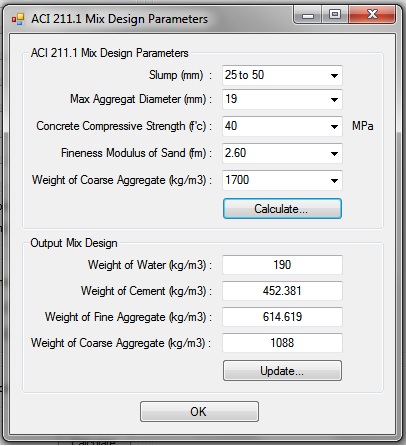

First Step. The algorithm for ACI 211.1 Mix Design is using the ITS Mix Design ACI 211.1 engine [3]. Figure 1b shows the input form for the mixture proportion based on ACI 211.1. The form can be accessed by clicking VRCPT Parameters >>> ACI 211.1 Mix Design Properties menu as shown in Figure 1a.

Figure 1a Guide to ACI 211.1 Mix Design Parameters

Figure 1b. ACI 211.1 Mix Design Parameters

Figure 1b shows the input parameters which are the Slump, Max. Aggregate Diameter, Concrete Compressive Strength (f’c), Fineness Modulus of Sand (fm) and Weight of Coarse Aggregate. The “Calculate” Button will compute the mix design proportion based on the input data, and the result is shown in Figure 1b. To update the main form value of mix design proportion, click the “Update” Button.

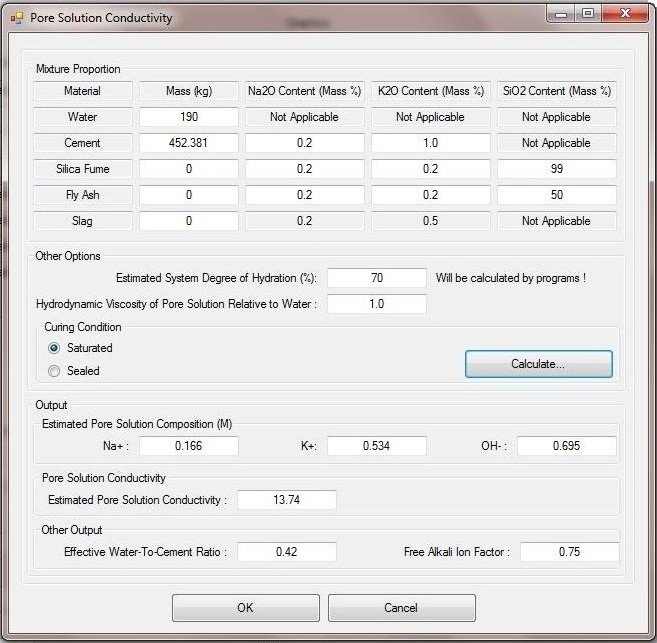

Second Step. Compute the value of the Pore Solution Conductivity (PSC). Figure 2 shows the input parameter of Pore Solution Conductivity. The input data are the materials compound involved in the mix design which consists of Na2O, K2O and SiO2 content as weight percentage. The Estimated System Degree of Hydration (%) is computed by the program automatically. The curing condition of the specimen will also give an effect to the Estimate Pore Solution Conductivity; the default value is in Saturated Condition. The output values consist of Estimated Pore Solution Composition (M), Pore Solution Conductivity, Effective Water to Cement Ratio and Free Alkali Ion Factor. The “OK” button will automatically update the PSC value in the main form.

Figure 2. Pore Solution Conductivity Parameters

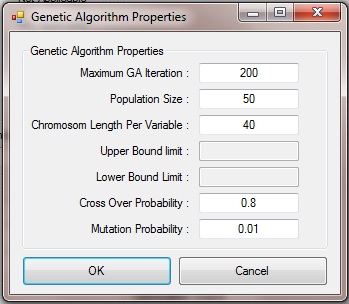

Third Step. Set the Genetic Algorithm properties as shown in Figure 3. This form can be accessed directly from VRCPT Parameter menu. The suggested value for the GA parameter is shown in Figure 3. The parameters in GA consist of Maximum GA Iteration, Population Size, Chromosom Length per Variable, Cross Over Probability and Mutation Probability.

Figure 3. Genetic Algorithm Properties

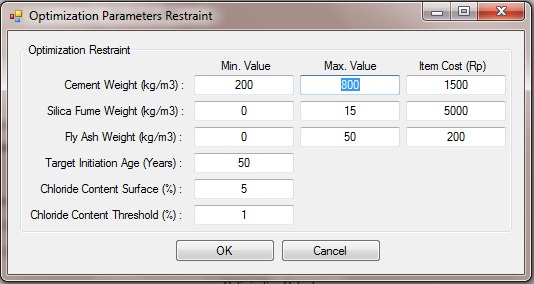

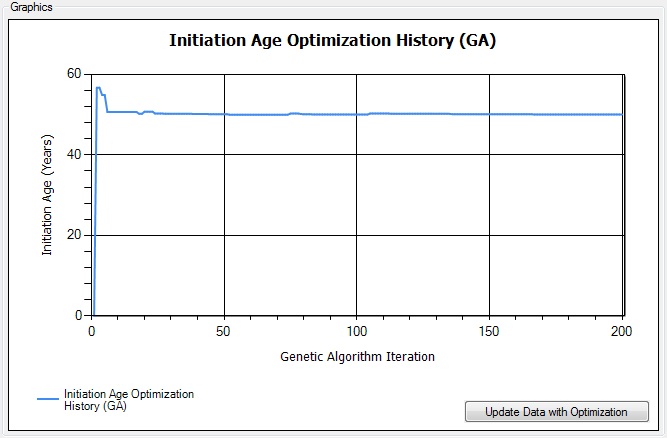

As for the boundary condition, in this research, the parameters is set based on the initial condition of chloride content at the concrete surface and at the steel rebar location (threshold), the maximum and minimum cost of material, and the target initiation time in years. Figure 4 shows the optimization parameters restraint. In this tutorial, the Cement Weight is set to minimum weight about 200 kg and maximum weight about 800 kg also the cost of cement per unit weight in kg is IDR (Indonesian Rupiah) 1500. The silica fume is set to minimum weight about 0 kg and maximum weight about 15 kg also the cost of silica fume per unit weight in kg is IDR 5000. The fly ash is set to minimum weight about 0 kg and maximum weight about 50 kg also the cost of fly ash per unit weight in kg is IDR 200. The target initiation time is set to 50 Years which means that the computed chloride penetration initiation time must not less than 50 years. Chloride content in the concrete surface is set to 5 % which is common to most of environment and chloride content threshold is set as the condition where the initiation of chloride penetration start to corrode the steel rebar.

Figure 4. Optimization Parameter Restraint

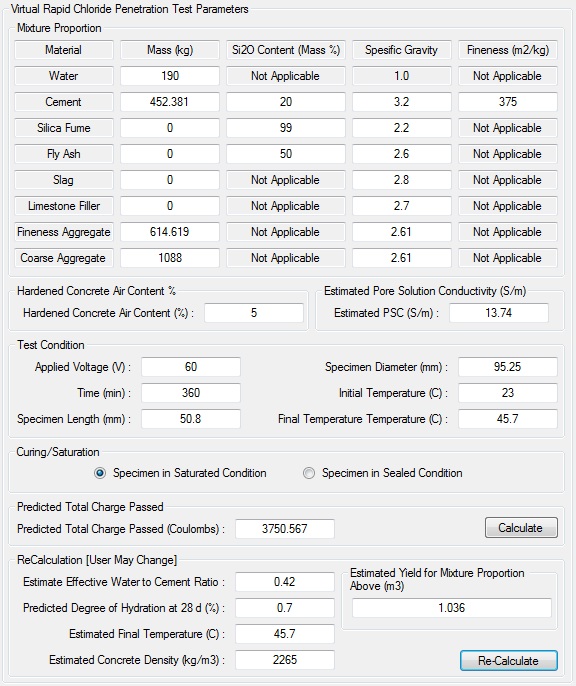

Figure 5 shows the main input form to compute the Total Charge Passed (TCP). We need to set the test condition, where the value in the main form is the standard value according to ASTM C1202 [4]. The difference is the initial temperature and final temperature should be set first. However, at the end of the form, “Re-Calculate” button is placed to simplify the change in the final temperature. After the test condition and curing condition have been set, then we can click the “Calculate” button to compute the Total Charge Passed (TCP).

Figure 5. Main Form TCP

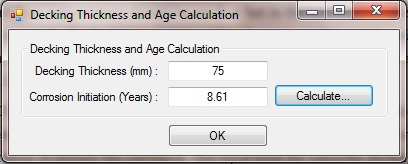

After the TCP is calculated, the initiation time of chloride penetration with a given concrete cover thickness can be computed. The input form for concrete cover thickness can also be accessed in the VRCPT Parameters Menu. Figure 6 show the input for the concrete cover thickness which is set to 75 mm and results in the chloride penetration initiation time with the current concrete mixture composition is 8.61 years.

Figure 6. Concrete Cover Thickness and Chloride Penetration Initiation Time Calculation Form

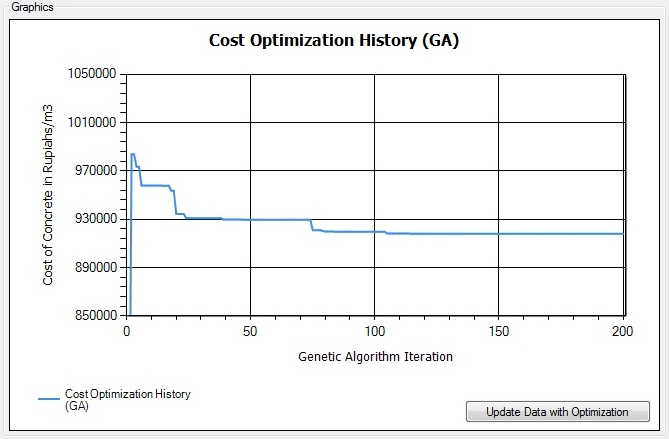

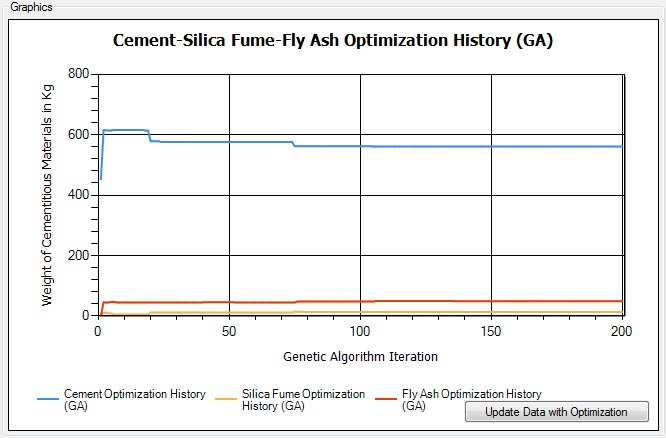

Genetic Algorithm Optimization. The step by step above shown on how to compute the initiation time with specific mixture composition. However, we can also used the genetic algorithm to find the most economical and efficient mixture proportion with specific initiation time. All the parameters required to optimized the concrete mixture composition has been set and to proceed with the optimization, we just need to click the “Run Optimization” button under Analysis Menu.

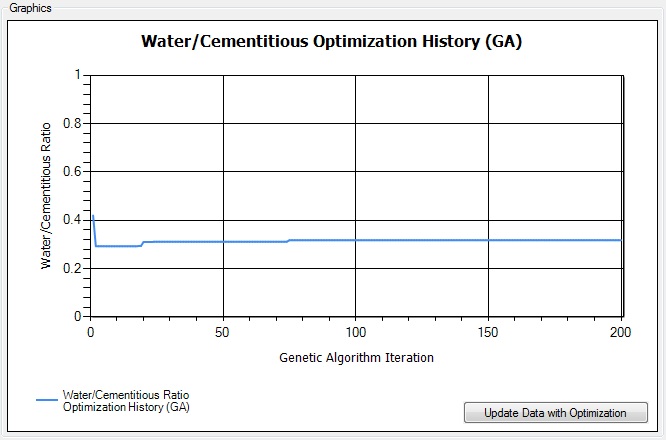

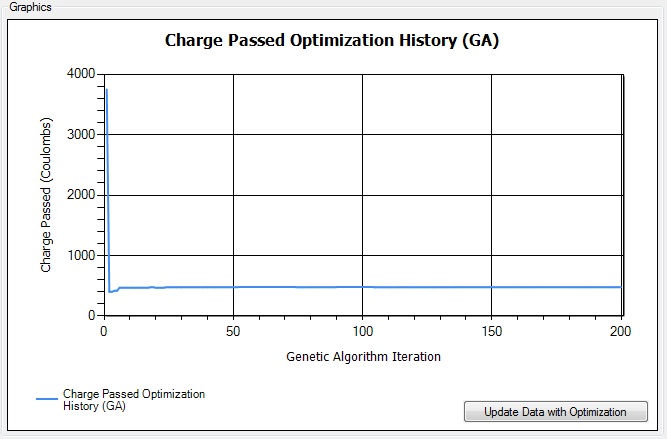

The output graphs which can be shown consists of Cost vs GA Iteration, Cement-Silica fume-Flyash vs GA Iteration, Water-Cement-Ratio vs GA Iteration, Charge-Passed-Coulomb vs GA Iteration and Initiation Age vs GA Iteration. Each graphs are shown in Figure 7a, Figure 7b, Figure 7c, Figure 7d and Figure 7e.

Figure 7a. Cost vs GA Iteration

Figure 7b. Cement-Silicafume-Flyash vs GA Iteration

Figure 7c. Water-Cement-Ratio vs GA Iteration

Figure 7d. Charge-Passed-Coulomb vs GA Iteration

Figure 7e. Initiation Age vs GA Iteration

Conclusion. This article present a computer program which is able to compute the optimum concrete mixture composition which depends on the desired concrete permeability. The concrete mixture composition is prepared using ACI 211.1 which valid for normal strength concrete. The concrete permeability is numerically estimated using VRCPT and the initiation time of the chloride penetration is computed using one dimensional 2nd Fick’s law. The optimum concrete mixture composition is found by using the genetic algorithm optimization.

References:

[1] Bentz DP. 2007. A virtual rapid chloride permeability test. Elsevier – Cement and Concrete Composites.

[2] Piscesa B., Irmawan M. 2010. Optimization of Concrete Mix Design With Determined Permeability Against Chloride Penetration Based On “Virtual Rapid Chloride Permeability Test” Using Genetic Algorithm. 2nd International Symposium on Life Cycle Engineering, At Taiwan Tech, Taipei, Taiwan.

[3] Piscesa B. 2008. ITS Mix Design using ACI 211.1 computer program.

[4] ASTC 1202 – Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration.